Anyway, a few weeks ago my brother called me to ask if I could sew something for him: sails for a model sailing ship. He buttered me up first, saying that it would be easy for me because it was just like sewing the clothing I used to make. "Just cut the fabric using the pattern pieces and hem them." Well, sure I could do that.

First, what's interesting to note, is that this ship is a model my dad bought about 25 years ago as a project to fill a difficult time in his life when my mom entered a nursing home in a new city, and he moved from their home to a condo near my brother's home and Mom's care center. The model is the Bluenose II, a Canadian schooner that was built in 1963 to celebrate the original Bluenose, which was a fishing and racing schooner, I think, built in the early 1920's.The Bluenose II is still in use to celebrate the maritime history of Nova Scotia. You can read about it at the schooner's website. The model was a product of a company called Artesania Latina, which I think is no longer in business. Dad built the hull, tiny board by tiny board. When he got to the rigging and sails, he quit. For years, the ship sat on a table in his basement. Recently, my brother took it home, thinking it might be a good project to work on someday during retirement. He didn't get around to it until life as we knew it shut down. Suddenly, he had all kinds of time on his hands. Someday had come.

More rigging:

And then here is where I came in. So the package arrived in the mail with the pattern, instructions, "sail" cloth, and little coil of rope. I wish I had taken a photo. The envelope was all wrinkly, like it had been sprayed with something. Disinfectant, maybe? The tape that sealed it was totally loose except for two inches at one end. I do know the postal service between our two cities was going through an especially hard time, so who knows what happened. Luckily, a check with my brother indicated that there was nothing missing.

And the instructions. Oh, wow, the instructions! It's a good thing I did not see these before I agreed. But you know what? My brother did charm me. Oh, yes he did. He followed those instructions to the letter. The underlined parts are what I was to do. But read the whole paragraph. (The little side note is his.) Yikes!

So anyway, initially I thought I was cutting out sails and hemming them. But then more was revealed. I'd have to sew little parallel lines on each sail to mimic the seams of real sails. . Oh, yeah and then I'd have to sew a tiny rope around each sail. By hand!. And everything was tiny, tiny. What had I gotten myself into?!!

Here's a drawing of the sails:

And the pattern:

The first thing I did was search for thread. Remember, this was during stay-at-home orders, so I had to work with what I had on hand. I auditioned some and sent my brother a photo for his input.

The Superior Masterpiece thread in Granite on the right was a perfect match for stitching the hems. It's a fine thread, so that was good for the scale of the project, too. The rope on the left is an olive-gray. I had just the right color in a hand quilting thread to match it. At first my brother said he wanted thread to match the sails for the parallel lines, but by the time he sent the package he said he had seen a photo of a model online with black for the lines that he liked better. Well, of course he did because that would be a doozy to sew straight (ha!). I laid out some black and gray all-purpose thread, and then a variegated gray quilting thread that I had left over from a project (Superior King Tut in Pumice). I thought the black was too stark. My brother chose the King Tut. Yay!

Using a scrap, I made a practice hem to see how it would work out. The instructions were to double-fold a .5cm (that's two folds of 2.5 mm!!) edge and top-stitch to hem. The good thing was that the fabric was crispy, so it held a pressed edge well, but it was also ravelly. I was able to stitch the tiny hem, but could not see myself in that much stress for all of them with the threat of everything raveling. So instead, I added a bit to the seam allowance and carefully traced and cut out the sails (there was no room for error as the fabric piece was about the same size as the pattern). My finished seams ended up being a tad over 1/8 inch, which was just fine with my brother, although a model ship builder would probably be appalled at the scale.

After I hemmed the sails I laid each one out on its pattern piece and traced the "seam" lines on the sails with a fine mechanical pencil, as I knew there was no way I could get straight lines by eyeball or with a seam guide.

Sewing all those lines was a slow task. I had not realized it before, but sewing through just one layer of fabric is a different kind of sewing. When you sew two (or more) layers together, the intertwining of the top and bobbin threads happens in between the layers. With a single layer of fabric, there is no place for that to happen. I had to turn up the top tension all the way on my machine to get the threads to lay straight on both sides of the sail--important, as in a model, the ship can be viewed from both sides. And, again because of scale, the stitches had to be very tiny. I had to rely on my trusty seam ripper to take out some lines when the tension failed. I also had to take apart the tension mechanism on my Featherweight several times to get it working properly again. Thanks to multiple videos online I was able to do that, but my machine is finicky, and often the numerical dial didn't want to seat. The definition of insanity is to do the same thing over and over again expecting different results. Well, I was insane, but it worked and eventually, after a lot of sweating and thinking,"Oh, no, I've wrecked it, and now I have to get it repaired, but the repair shop is closed for who knows how long," the mechanism would pop back together. Whew. Now I know my machine a whole lot better.

Pay no attention to that 6 on the dial. The tension dial was actually turned all the way tight. (This was before I had taken it apart and adjusted it. Now my numbers actually match the tension, but if you know Singer machines, you know that's just arbitrary anyway.) The lines look a bit wavy on the crispy fabric from this angle, but they are straight enough when you look at them straight on.

Eventually, the sails were all hemmed and lined:

So far, so good. I had to work up my courage for the next step--the hand sewing to attach the bolt ropes with eye splices to each edge of all the sails. (Yes, I do know some ship terminology now.) I started with a sample piece again. (Photos are ones I sent to my brother for his approval of the process.)

I had to whip thread around the edge, piercing the rope to keep it in place, but also allow enough room for tiny rings to fit through to attach the sails to masts and other things (that I don't know the names of). I also tried lashing the ends of the rope together, but it was really too thick to suit me so I tried other means of joining them when I actually sewed them to the sails--mostly stitching them just past each other with a dot of glue to keep them from raveling.The eye splice is that little loop you see at the corner that gets attached to ship parts (no, I don't know the term) by lines (no, I don't know the term for those, either).

Here is the other side:

The stitches are a little more angled, but they are consistent, so I think it's fine. I have since thought of a way to do that stitching that would be invisible, but I think I'd still be sewing these if I had used it.

And one more view with a paper clip standing in for a ring to make sure there was enough space to attach the rings:

Once I had that done, I worked several hours a day for a week--I kid you not--to do this tiny stitching. I quickly found that I needed to do it in natural daylight. My tired old eyes could not do the job in lamp light. But it got done. Here are all the sails, along with a flag.

Oh, yeah, the flag. That was just one more teensy project my brother came up with. There is supposed to be a Canadian flag on the ship, but since we had been working on this project during stay-at-home time, he decided on a quarantine flag instead. He had printed out a paper one, but could I maybe make a fabric one? Hmm. A sewn flag would have looked more like a quilt. Too bulky. So I scrounged around and found a scrap of fusible web and just fused tiny squares of fabric scraps (yup, I've got those) together so that it would look like a proper flag from both sides. I was beginning to think my part of the project would never end! But it did!! And I'm pretty proud of my part of it.

Here's a close-up:

And more sail shots:

And the back of one:

Because of the condition of the package when my brother sent me the sail materials, he was not comfortable with having me mail them back to him. One morning, feeling antsy with staying at home, he called and said he was going to drive out to get them so he could finish the ship. We had previously talked about meeting halfway, but I was not comfortable leaving my house without a way to stop at a "comfort station" if I needed it on the way. So denying himself coffee so he wouldn't have to stop (see, you can talk about any subject during a quarantine), he drove nearly 90 miles from his home to pick up the sails on my front porch. We visited through the front door glass for a few minutes and then he turned around and drove home. (Wish I had thought to take a photo.)

He sent me progess photos of attaching the sails to the ship, which I think was probably as much work as making them.

After attaching the first three sails, he decided to keep one furled to make it a little less cluttered and maybe more exciting.

More sails:

And done!!

So there you have it: my squirrel project during quarantine. Well, actually, our squirrel project, but I don't think my brother knew it was a squirrel. An amazing amount of work! Now I really appreciate what all goes into making a model. When I was a kid, my dream was to build a miniature doll house. (I think that dream came from seeing the fairy castle at the Museum of Science and Industry in Chicago.) I never got around to it (except for a cardboard one that got destroyed in a minor flood in our basement when I was about 11 or so), but I have to say I'm still fascinated by miniatures. I'm not into ships so much, but the idea is the same, right? Building something tiny with as much detail as possible to resemble the real thing. But my eyes are not what they used to be, and while I learned a lot about making model sails, but I doubt I will make them again. I also realize that the doll house dream is just an appreciation now.

If you've been keeping track, you know now that my father, my brother, and I have all had a hand in this project. But there's more. The sewing machine is the one my mom got second-hand when she married my dad nearly 69 years ago. She left us more than 22 years ago, but her Featherweight is still my primary sewing machine. So this was truly a project that our whole family had a part in. Isn't that wonderful?

It was fun texting back and forth, sharing photos with my brother, and keeping my dad up-to-date on the progress. And then, actually finishing a model started so many years ago! I wonder how many hours we spent in total. Mind-boggling, probably. My dad is thrilled. Of course, being practical, he says he's just glad it's done because he "paid a lot for it." It's on display at my brother's house for now. Maybe when we are all a little freer to move around, my dad can show it off at his condo. He did get to see it during a physically-distanced quick peek.

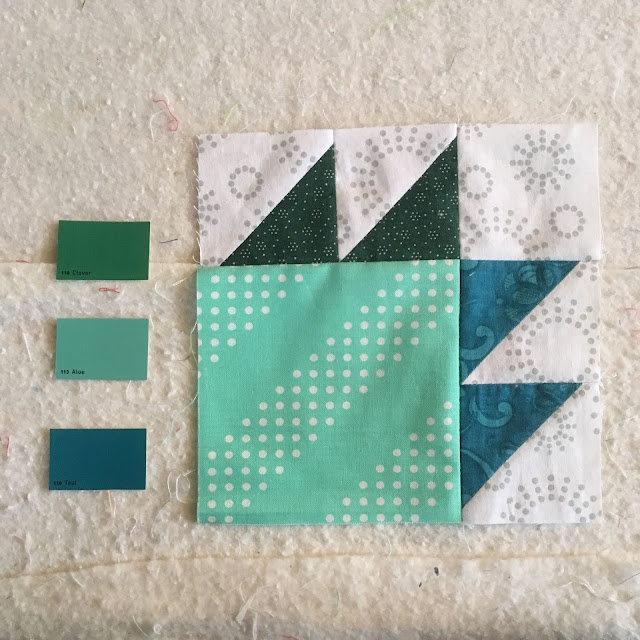

I'm linking up with Sandra at mmm! quilts for DrEAMi (Drop Everything And Make it) even though it's not a quilt. Hey, it was a squirrel after all, and does relate somehow to Canada, too, so I think she'll be okay with it. And once I got these sails done, you can bet I went back to quilting with a new appreciation for those big (ha ha) quarter-inch seams. I even got two tops together, and one of them basted. Here are just a couple of peeks at those.

I'm linking up with Sandra at mmm! quilts for DrEAMi (Drop Everything And Make it) even though it's not a quilt. Hey, it was a squirrel after all, and does relate somehow to Canada, too, so I think she'll be okay with it. And once I got these sails done, you can bet I went back to quilting with a new appreciation for those big (ha ha) quarter-inch seams. I even got two tops together, and one of them basted. Here are just a couple of peeks at those.

I'm wondering what's got you distracted these days. There's plenty to distract. But I hope it is something good, and maybe even something quilty.

(Just a reminder: I'm not affiliated with any company, so when I mention products, services, or stores I'm just documenting what I used or liked.)

And the instructions. Oh, wow, the instructions! It's a good thing I did not see these before I agreed. But you know what? My brother did charm me. Oh, yes he did. He followed those instructions to the letter. The underlined parts are what I was to do. But read the whole paragraph. (The little side note is his.) Yikes!

So anyway, initially I thought I was cutting out sails and hemming them. But then more was revealed. I'd have to sew little parallel lines on each sail to mimic the seams of real sails. . Oh, yeah and then I'd have to sew a tiny rope around each sail. By hand!. And everything was tiny, tiny. What had I gotten myself into?!!

Here's a drawing of the sails:

And the pattern:

The first thing I did was search for thread. Remember, this was during stay-at-home orders, so I had to work with what I had on hand. I auditioned some and sent my brother a photo for his input.

The Superior Masterpiece thread in Granite on the right was a perfect match for stitching the hems. It's a fine thread, so that was good for the scale of the project, too. The rope on the left is an olive-gray. I had just the right color in a hand quilting thread to match it. At first my brother said he wanted thread to match the sails for the parallel lines, but by the time he sent the package he said he had seen a photo of a model online with black for the lines that he liked better. Well, of course he did because that would be a doozy to sew straight (ha!). I laid out some black and gray all-purpose thread, and then a variegated gray quilting thread that I had left over from a project (Superior King Tut in Pumice). I thought the black was too stark. My brother chose the King Tut. Yay!

Using a scrap, I made a practice hem to see how it would work out. The instructions were to double-fold a .5cm (that's two folds of 2.5 mm!!) edge and top-stitch to hem. The good thing was that the fabric was crispy, so it held a pressed edge well, but it was also ravelly. I was able to stitch the tiny hem, but could not see myself in that much stress for all of them with the threat of everything raveling. So instead, I added a bit to the seam allowance and carefully traced and cut out the sails (there was no room for error as the fabric piece was about the same size as the pattern). My finished seams ended up being a tad over 1/8 inch, which was just fine with my brother, although a model ship builder would probably be appalled at the scale.

After I hemmed the sails I laid each one out on its pattern piece and traced the "seam" lines on the sails with a fine mechanical pencil, as I knew there was no way I could get straight lines by eyeball or with a seam guide.

Sewing all those lines was a slow task. I had not realized it before, but sewing through just one layer of fabric is a different kind of sewing. When you sew two (or more) layers together, the intertwining of the top and bobbin threads happens in between the layers. With a single layer of fabric, there is no place for that to happen. I had to turn up the top tension all the way on my machine to get the threads to lay straight on both sides of the sail--important, as in a model, the ship can be viewed from both sides. And, again because of scale, the stitches had to be very tiny. I had to rely on my trusty seam ripper to take out some lines when the tension failed. I also had to take apart the tension mechanism on my Featherweight several times to get it working properly again. Thanks to multiple videos online I was able to do that, but my machine is finicky, and often the numerical dial didn't want to seat. The definition of insanity is to do the same thing over and over again expecting different results. Well, I was insane, but it worked and eventually, after a lot of sweating and thinking,"Oh, no, I've wrecked it, and now I have to get it repaired, but the repair shop is closed for who knows how long," the mechanism would pop back together. Whew. Now I know my machine a whole lot better.

Pay no attention to that 6 on the dial. The tension dial was actually turned all the way tight. (This was before I had taken it apart and adjusted it. Now my numbers actually match the tension, but if you know Singer machines, you know that's just arbitrary anyway.) The lines look a bit wavy on the crispy fabric from this angle, but they are straight enough when you look at them straight on.

Eventually, the sails were all hemmed and lined:

So far, so good. I had to work up my courage for the next step--the hand sewing to attach the bolt ropes with eye splices to each edge of all the sails. (Yes, I do know some ship terminology now.) I started with a sample piece again. (Photos are ones I sent to my brother for his approval of the process.)

I had to whip thread around the edge, piercing the rope to keep it in place, but also allow enough room for tiny rings to fit through to attach the sails to masts and other things (that I don't know the names of). I also tried lashing the ends of the rope together, but it was really too thick to suit me so I tried other means of joining them when I actually sewed them to the sails--mostly stitching them just past each other with a dot of glue to keep them from raveling.The eye splice is that little loop you see at the corner that gets attached to ship parts (no, I don't know the term) by lines (no, I don't know the term for those, either).

Here is the other side:

The stitches are a little more angled, but they are consistent, so I think it's fine. I have since thought of a way to do that stitching that would be invisible, but I think I'd still be sewing these if I had used it.

And one more view with a paper clip standing in for a ring to make sure there was enough space to attach the rings:

Once I had that done, I worked several hours a day for a week--I kid you not--to do this tiny stitching. I quickly found that I needed to do it in natural daylight. My tired old eyes could not do the job in lamp light. But it got done. Here are all the sails, along with a flag.

Oh, yeah, the flag. That was just one more teensy project my brother came up with. There is supposed to be a Canadian flag on the ship, but since we had been working on this project during stay-at-home time, he decided on a quarantine flag instead. He had printed out a paper one, but could I maybe make a fabric one? Hmm. A sewn flag would have looked more like a quilt. Too bulky. So I scrounged around and found a scrap of fusible web and just fused tiny squares of fabric scraps (yup, I've got those) together so that it would look like a proper flag from both sides. I was beginning to think my part of the project would never end! But it did!! And I'm pretty proud of my part of it.

Here's a close-up:

And more sail shots:

And the back of one:

Because of the condition of the package when my brother sent me the sail materials, he was not comfortable with having me mail them back to him. One morning, feeling antsy with staying at home, he called and said he was going to drive out to get them so he could finish the ship. We had previously talked about meeting halfway, but I was not comfortable leaving my house without a way to stop at a "comfort station" if I needed it on the way. So denying himself coffee so he wouldn't have to stop (see, you can talk about any subject during a quarantine), he drove nearly 90 miles from his home to pick up the sails on my front porch. We visited through the front door glass for a few minutes and then he turned around and drove home. (Wish I had thought to take a photo.)

He sent me progess photos of attaching the sails to the ship, which I think was probably as much work as making them.

After attaching the first three sails, he decided to keep one furled to make it a little less cluttered and maybe more exciting.

More sails:

And done!!

|

| I think the last sail is furled behind the others. |

If you've been keeping track, you know now that my father, my brother, and I have all had a hand in this project. But there's more. The sewing machine is the one my mom got second-hand when she married my dad nearly 69 years ago. She left us more than 22 years ago, but her Featherweight is still my primary sewing machine. So this was truly a project that our whole family had a part in. Isn't that wonderful?

It was fun texting back and forth, sharing photos with my brother, and keeping my dad up-to-date on the progress. And then, actually finishing a model started so many years ago! I wonder how many hours we spent in total. Mind-boggling, probably. My dad is thrilled. Of course, being practical, he says he's just glad it's done because he "paid a lot for it." It's on display at my brother's house for now. Maybe when we are all a little freer to move around, my dad can show it off at his condo. He did get to see it during a physically-distanced quick peek.

I'm wondering what's got you distracted these days. There's plenty to distract. But I hope it is something good, and maybe even something quilty.

(Just a reminder: I'm not affiliated with any company, so when I mention products, services, or stores I'm just documenting what I used or liked.)